Placeholders Variables¶

Built-in placeholder variables exposed by OrcaSlicer when expanding custom G-code snippets and template expressions.

- Conventions

- Global Slicing State

- Slicing State

- Print Statistics

- Objects

- Plates

- Dimensions

- Temperatures

- Timestamps

- Environment

- Preset Metadata

- Filename Templates

- Custom G-code Contexts

Conventions¶

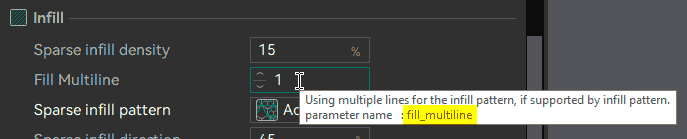

- Placeholder names are case sensitive and follow the same snake_case keys that appear in the UI tooltips and configuration files.

- Brackets (

[]) mark vector-valued options. Extruder-scoped vectors default to the currently active extruder when no index is provided; specify a zero-based index (bed_temperature[1]) to query another tool. Object or plate-scoped arrays always require an explicit zero-based index. - Unless noted otherwise distances are in millimetres, temperatures in °C, volumes in mm³, weights in grams, feedrates in mm/min, and booleans return

0/1. - Points and bounding boxes are stored as

[x, y]pairs expressed in mm. layer_numis one-based (first layer is1). All other indices use zero-based numbering.- Every print/filament/printer setting is also available under its config key. Hover the label in the UI to see the key. The tables below focus on additional runtime placeholders.

Global Slicing State¶

Momentary toolhead state when a custom G-code block runs.

Read Only¶

| Placeholder | Type | Description |

|---|---|---|

zhop |

float (mm) | Z-hop height present when the custom block starts. |

Read Write¶

| Placeholder | Type | Description |

|---|---|---|

position[] |

float[3] (mm) | XYZ position of the tool when control entered the custom block. Update this if you move the tool so the slicer keeps continuity. |

e_position[] |

float per extruder (mm) | Absolute extruder axis position, used only when the G-code uses absolute E coordinates. |

e_retracted[] |

float per extruder (mm) | Retraction state at block entry. Update when you manually retract or unretract so OrcaSlicer can compensate afterwards. |

e_restart_extra[] |

float per extruder (mm) | Planned extra priming after the next de-retraction. |

Slicing State¶

Tracks which extruder, object, and priming helpers are active during the current print.

| Placeholder | Type | Description |

|---|---|---|

current_extruder |

int | Zero-based index of the extruder currently emitting G-code. |

current_object_idx |

int | Zero-based index of the object being printed (used by sequential printing). |

has_wipe_tower |

bool | true when a wipe tower is present in the job. |

has_single_extruder_multi_material_priming |

bool | Indicates whether the single-extruder MMU priming area is in use. |

initial_extruder / initial_tool |

int | First extruder used in the print. Both placeholders expose the same value. |

initial_no_support_extruder |

int | First extruder that prints without supports (also used for no-support prime). |

is_extruder_used[] |

bool per extruder | Reports whether each extruder participates in the job. |

num_extruders |

int | Total number of configured extruders, regardless of usage in the current print. |

retraction_distance_when_cut |

float (mm) | Distance used when cutting filament (AMS / cutter retraction) for the current extruder. |

long_retraction_when_cut |

bool | true when the “long retraction when cut” behaviour is enabled for the active extruder. |

in_head_wrap_detect_zone |

bool | true if the first layer intersects the head-wrap detection area. |

Print Statistics¶

Summaries of the sliced job such as time estimates, material usage, and wipe-tower costs.

| Placeholder | Type | Description |

|---|---|---|

normal_print_time / print_time |

string (hh:mm:ss) |

Estimated print duration in normal mode. Both placeholders expose the same value. |

silent_print_time |

string (hh:mm:ss) |

Estimated print duration in silent mode. |

total_layer_count |

int | Number of sliced layers. |

total_toolchanges |

int | Number of planned tool changes (including wipe tower changes). |

used_filament |

float (mm) | Total filament length consumed by the entire job. |

extruded_volume[] |

float per extruder (mm³) | Volume extruded by each extruder. |

extruded_volume_total |

float (mm³) | Sum of extruded_volume[]. |

extruded_weight[] |

float per extruder (g) | Material weight per extruder (via filament density). |

extruded_weight_total / total_weight |

float (g) | Sum of extruded_weight[]. |

total_cost |

float (currency) | Combined material cost computed from filament cost settings. |

total_wipe_tower_cost |

float (currency) | Portion of total_cost spent on the wipe tower. |

total_wipe_tower_filament |

float (mm³) | Total volume extruded on the wipe tower. |

Objects¶

Metadata describing the loaded models and their instances.

| Placeholder | Type | Description |

|---|---|---|

num_objects |

int | Number of distinct objects on the plate. |

num_instances |

int | Count of all printed instances across every object. |

scale[] |

string per object | Human-readable scale applied to each object (zero-based object index). Example: x:100% y:50% z:100%. |

input_filename_base |

string | Source filename of the first imported object without the extension. |

input_filename |

string | Full filename (with extension) of the first imported object. |

Plates¶

Metadata describing the currently selected plates.

| Placeholder | Type | Description |

|---|---|---|

plate_name |

string | Name of the active plate. |

Dimensions¶

Geometric measurements of the first layer and printable bed area, useful for positioning macros.

| Placeholder | Type | Description |

|---|---|---|

first_layer_print_convex_hull |

array of [x, y] pairs (mm) |

Polygon describing the convex hull of the first layer. |

first_layer_print_min |

float[2] (mm) | Bottom-left corner of the first-layer bounding box. |

first_layer_print_max |

float[2] (mm) | Top-right corner of the first-layer bounding box. |

first_layer_print_size |

float[2] (mm) | Width and depth of the first-layer bounding box. |

first_layer_center_no_wipe_tower |

float[2] (mm) | Center of the first layer excluding the wipe tower footprint. |

first_layer_height |

float (mm) | Height of the first printed layer. |

print_bed_min |

float[2] (mm) | Bed bounding box minimum (bottom-left corner). |

print_bed_max |

float[2] (mm) | Bed bounding box maximum (top-right corner). |

print_bed_size |

float[2] (mm) | Width and depth of the printable area. |

Temperatures¶

Bed, nozzle, and chamber set-points taken directly from the filament profiles.

| Placeholder | Type | Description |

|---|---|---|

bed_temperature[] |

int per extruder (°C) | Bed temperature associated with each extruder/filament. |

bed_temperature_initial_layer[] / first_layer_bed_temperature[] |

int per extruder (°C) | Initial-layer bed temperatures. |

bed_temperature_initial_layer_single |

int (°C) | Initial-layer bed temperature for initial_extruder. |

first_layer_temperature[] |

int per extruder (°C) | Initial-layer nozzle temperatures. |

chamber_temperature[] |

int per extruder (°C) | Chamber set-point requested for each filament. |

overall_chamber_temperature |

int (°C) | Maximum of chamber_temperature[] across the extruders used in the job. |

Timestamps¶

Timestamp components information recorded when slicing began.

| Placeholder | Type | Description |

|---|---|---|

timestamp |

string (yyyyMMdd-hhmmss) |

Local timestamp captured when slicing ran. |

year / month / day |

int | Gregorian date components of timestamp. |

hour / minute / second |

int | Time-of-day components of timestamp. |

Any shell environment variable whose name starts with SLIC3R_ is also imported as a placeholder under the same key, allowing you to pass ad-hoc values into a slice (for example SLIC3R_BUILD_TAG).

Environment¶

Runtime environment information.

| Placeholder | Type | Description |

|---|---|---|

user |

string | Username resolved from USER/USERNAME environment variables (falls back to unknown). |

version |

string | OrcaSlicer version string. |

Preset Metadata¶

Names of the print, filament, and printer presets that provided the configuration values.

| Placeholder | Type | Description |

|---|---|---|

print_preset |

string | Name of the active print preset. |

filament_preset[] |

string per extruder | Preset name for each filament slot. Use [idx] to target a specific extruder. |

filament_type[] |

string per extruder | Material type label reported by each filament preset (PLA, PETG, ABS, etc.). |

printer_preset |

string | Logical printer preset used for slicing. |

Tip

Others items shares its config key with the placeholder name.

Hover the label to discover the key.

Filename Templates¶

Notes about the limited placeholder set that is available when OrcaSlicer builds the export filename.

The slicer resolves filename_format before any G-code is produced (see Print::output_filename).

Only placeholders that are already present in the global parser at that time can be used in the exported file name:

- Configuration keys from the active print/filament/printer presets, including

print_preset,filament_preset[],printer_preset, and every regular setting (line widths, temperatures, etc.). - Object metadata injected up front:

input_filename,input_filename_base,num_objects,num_instances,scale[],plate_name,model_name, plus the timestamp and user placeholders. - Print statistics computed right after slicing such as

print_time,normal_print_time,silent_print_time,used_filament,extruded_volume,total_cost,total_toolchanges,total_weight, and wipe-tower totals.

Placeholders that are populated later, during per-layer or per-tool G-code generation, are not available inside filename_format. This includes everything under Global Slicing State, Slicing State, Layer-aware, Toolchange, Filament start/end, Timelapse, Extrusion role, and Pause/color change helpers. Using them in templates causes filename evaluation to fail because they are unset when the template is processed.

Custom G-code Contexts¶

Runtime-only placeholders injected right before specific custom G-code hooks are evaluated.

In addition to the global placeholders above, OrcaSlicer injects context-specific values when it evaluates individual G-code macros.

Layer-aware placeholders¶

| Placeholder | Type | Description |

|---|---|---|

layer_num |

int (1-based) | Current layer index. Provided to before_layer_change_gcode, layer_change_gcode, timelapse_gcode, wrapping_detection_gcode, change_filament_gcode, filament_start_gcode, filament_end_gcode, and machine_end_gcode. |

layer_z |

float (mm) | Height of the top of the current layer (after applying any Z offset). Available in the same contexts as layer_num. |

max_layer_z |

float (mm) | Z height of the final layer. Available anywhere a layer-aware macro runs (layer change, timelapse, wrapping detection, change filament, filament start/end, machine end). |

filament_extruder_id |

int | Zero-based ID of the extruder whose macro is executing. Provided to filament start/end scripts, machine end G-code, change filament/path scripts, and other macros that need to know the current tool. |

Toolchange and wipe tower placeholders¶

The following placeholders are populated only while change_filament_gcode (and the wipe-tower driven toolchange flow) is being evaluated.

| Placeholder | Type | Description |

|---|---|---|

previous_extruder / next_extruder |

int | IDs of the extruder being unloaded and the one being loaded. |

toolchange_z |

float (mm) | Actual Z height at the moment the toolchange macro is called. |

outer_wall_volumetric_speed |

float (mm³/s) | Volumetric speed limit for the new extruder’s outer walls. |

relative_e_axis |

bool | Indicates whether the slicer is emitting relative E moves (G91 E). |

toolchange_count |

int | Number of tool changes that have occurred so far. |

fan_speed |

int | Legacy placeholder kept for compatibility (always 0). |

old_retract_length / new_retract_length |

float (mm) | Retraction distance for the outgoing and incoming filaments. |

old_retract_length_toolchange / new_retract_length_toolchange |

float (mm) | Toolchange-specific retraction distances for each filament. |

old_filament_temp / new_filament_temp |

int (°C) | Requested nozzle temperatures before and after the toolchange. |

old_filament_e_feedrate / new_filament_e_feedrate |

int (mm/min) | Extrusion feedrates derived from volumetric limits for the old/new filaments. |

x_after_toolchange / y_after_toolchange / z_after_toolchange |

float (mm) | Position the slicer expects after the toolchange macro finishes. Update them if you move somewhere else. |

first_flush_volume / second_flush_volume |

float (mm of filament) | Each half of the planned purge length. |

flush_length |

float (mm of filament) | Total purge length requested for the toolchange. |

flush_length_1 … flush_length_4 |

float (mm of filament) | Individual purge segments (unused entries are 0). |

flush_volumetric_speeds[] |

float per extruder (mm³/s) | Calibration purge speeds associated with the flush sequence. |

flush_temperatures[] |

int per extruder (°C) | Temperatures to use for each stage of the flush sequence. |

wipe_avoid_perimeter |

bool | true when wipe tower travel avoidance is active for the change. |

wipe_avoid_pos_x |

float (mm) | X coordinate of the avoidance barrier used around the wipe tower. |

travel_point_1_x / travel_point_1_y |

float (mm) | First intermediate XY travel waypoint in object coordinates. |

travel_point_2_x / travel_point_2_y |

float (mm) | Second intermediate travel waypoint. |

travel_point_3_x / travel_point_3_y |

float (mm) | Third intermediate travel waypoint. |

All layer_* placeholders from the previous section are also available inside change_filament_gcode.

Filament start/end placeholders¶

| Placeholder | Type | Description |

|---|---|---|

filament_extruder_id |

int | ID of the filament whose start or end macro is executing. Present in filament_start_gcode, filament_end_gcode, and machine_end_gcode. |

retraction_distance_when_cut |

float (mm) | Cut-retraction distance for the active filament. Provided to filament_start_gcode (and as a global placeholder). |

long_retraction_when_cut |

bool | Whether the “long retraction when cut” behaviour is enabled for the active filament. Provided to filament_start_gcode and globally. |

filament_start_gcode and filament_end_gcode also receive the layer-aware placeholders listed earlier (layer_num, layer_z, max_layer_z).

Timelapse and wrapping detection¶

| Placeholder | Type | Description |

|---|---|---|

most_used_physical_extruder_id |

int | Physical extruder that prints most of the layer. Supplied to timelapse_gcode and wrapping_detection_gcode. |

curr_physical_extruder_id |

int | Physical extruder currently active when the macro runs. Provided to the same scripts as above. |

timelapse_pos_x / timelapse_pos_y |

int (mm) | XY coordinates selected for taking the snapshot. Available only inside timelapse_gcode. |

has_timelapse_safe_pos |

bool | Indicates whether a safe snapshot position was found. Available in timelapse_gcode. |

Extrusion role changes¶

| Placeholder | Type | Description |

|---|---|---|

extrusion_role |

string | Name of the extrusion role that the slicer is about to use (Perimeter, ExternalPerimeter, Support, etc.). Available in change_extrusion_role_gcode. |

last_extrusion_role |

string | Previous extrusion role before the transition. Available in change_extrusion_role_gcode. |

Pause / color change helpers¶

| Placeholder | Type | Description |

|---|---|---|

color_change_extruder |

int | Extruder index associated with a color-change (M600) event. Populated when OrcaSlicer triggers machine_pause_gcode for a color change. |

Use these tables as a reference when designing custom start/end sequences, toolchange macros, or template snippets. Combine them with preset-specific placeholders (e.g. nozzle_temperature, filament_diameter) to script advanced behaviours.